Have you ever felt the thrill of a powerful engine roaring to life, knowing the complex symphony of moving parts is working flawlessly? That feeling is a testament to meticulous engineering, and nowhere is that precision more evident than in the setting of rocker arm torque specs. For Mack E7 engine owners, understanding these specs is not just a matter of technical knowledge; it’s a vital key to ensuring optimal performance and extending the life of your valuable investment.

Image: www.2carpros.com

Today, we’ll dive into the world of Mack E7 rocker arm torque specs, exploring their significance, uncovering potential pitfalls, and ultimately empowering you with the knowledge to maintain your engine’s health and unlock its full potential.

Unlocking the Power of Torque: A Deep Dive into Mack E7 Rocker Arm Specs

The humble rocker arm might seem like a small component, but it plays a crucial role in the complex dance of engine power. Think of it as the conductor of the engine’s symphony, translating the force of the camshaft into the precise movement of the valves. And like a finely tuned orchestra, the rocker arm needs careful attention to ensure every note is played perfectly.

The Mack E7 engine, a workhorse known for its robust performance and durability, relies on precise rocker arm torque specs. These specs are more than just numbers on a page; they represent a meticulous balance between torque applied and potential damage. Setting the torque too tight can lead to premature valve stem wear, even cracking the rocker arm itself. Conversely, loose torque can cause rocker arm movement, leading to valve timing issues and ultimately affecting engine performance.

Crucial Considerations:

-

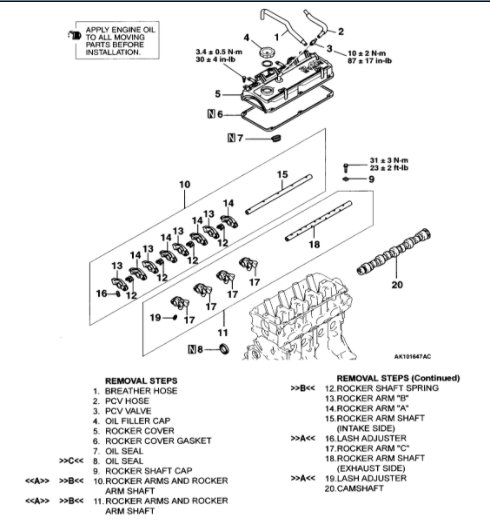

Engine Type: Mack E7 engines come in various configurations, with different torque specs specific to each model. It’s vital to identify your precise engine type (E7-300, E7-350, etc.) to ensure you’re using the correct specifications.

-

Rocker Arm Type: Mack E7 engines may incorporate different types of rocker arms, each with its own torque spec. Consulting your engine’s service manual or contacting a Mack dealer is essential for identifying the appropriate torque value.

-

Torque Wrench Accuracy: The accuracy of your torque wrench is paramount. A faulty wrench can lead to improper torque application, risking damage to your engine. Regularly calibrate your torque wrench to ensure its reliability.

The Right Tools for the Job: What You Need for Reliable Torque Setting

Setting the rocker arm torque on a Mack E7 engine is a task that demands precision and the right tools. Here’s what you’ll need to ensure a safe and effective procedure:

-

Torque Wrench: As mentioned earlier, a high-quality torque wrench is essential for accurate torque application. Choose a wrench with a range that covers the specific torque values required for your Mack E7 rocker arms.

-

Breaker Bar: A breaker bar provides leverage to loosen or tighten stubborn bolts, making your work easier. Choose a bar that’s compatible with the size of your rocker arm bolts.

-

Socket Set: A socket set with sizes appropriate for your engine’s rocker arm bolts is crucial for securing and removing them.

-

Workshop Manual: Having the specific workshop manual for your Mack E7 engine is invaluable. It provides detailed instructions, torque specs, and important warnings specific to your engine model.

-

Safety Glasses and Gloves: Always prioritize safety. Wear safety glasses to protect your eyes from any airborne debris and gloves to ensure a secure grip during the process.

The Art of Precision: A Step-by-Step Guide to Setting Rocker Arm Torque

Now that you have the necessary tools, let’s break down the process of setting rocker arm torque on a Mack E7 engine:

-

Preparation: Start by thoroughly cleaning the engine’s rocker arm area. Remove any debris or oil that might interfere with tightening the bolts. This ensures you’re working with a clean surface, avoiding potential damage caused by contamination.

-

Loosening the Bolts: Using your breaker bar and socket, carefully loosen the rocker arm bolts. Do not completely remove them at this stage.

-

Establishing a Starting Point: With the bolts loosened, use your torque wrench to apply the specified torque for your engine and rocker arm type. This establishes a consistent starting point for tightening each bolt.

-

Tightening in Sequence: Following the torque sequence specified in your workshop manual, tighten each rocker arm bolt to the required torque. The correct tightening sequence ensures even pressure distribution and prevents potential bending of the rocker arm.

-

Double-check and Repeat: Once you’ve tightened all bolts to the specified torque, carefully check and ensure they are still adequately tightened. If any bolt feels loose, tighten it back to the specified torque.

-

Final Verification: Run the engine briefly, ensuring no unusual noises or vibrations occur. If all seems normal, you’ve successfully set the rocker arm torque on your Mack E7 engine.

Image: truckpartsinventory.com

Expert Advice and Insights for Engine Longevity

While the steps above provide a solid foundation for setting rocker arm torque, expert advice can elevate your understanding and contribute to long-term engine health.

- Professional Guidance: For particularly complex engines or if you’re unsure about any aspect of the process, don’t hesitate to seek professional guidance. A qualified mechanic can ensure proper torque application and prevent potential damage.

- Regular Maintenance: Setting the rocker arm torque is just one aspect of maintaining your Mack E7 engine. Regular oil changes, valve adjustments, and other recommended maintenance procedures are crucial for maximizing your engine’s performance and lifespan.

Mack E7 Rocker Arm Torque Specs

Conclusion: Keeping Your Engine’s Heart Beating Strong

Understanding and implementing proper rocker arm torque settings is a critical element in ensuring the long and healthy life of your Mack E7 engine. By following the steps outlined in this guide and prioritizing expert advice when needed, you’ll be well-equipped to keep the engine’s symphony playing smoothly, giving you years of reliable performance and satisfaction.

Remember, preventive maintenance is key to avoiding costly repairs down the line. Invest in your Mack E7 engine by understanding its workings, prioritizing accurate torque settings, and seeking professional help when required. This commitment will pay off in the form of extended engine life and optimal performance, allowing you to experience the thrill of a powerful engine working flawlessly for years to come.