Have you ever wondered what it takes to keep workplaces safe and healthy? Ever considered the complex world of regulations that ensure worker well-being? This is where OSHA, the Occupational Safety and Health Administration, steps in. The OSHA 30-Hour General Industry Training course is a vital step for anyone involved in workplace safety, whether you’re a manager, supervisor, or even a curious employee. And if you’re preparing for the OSHA 30 General Industry test, this article is your guide to conquering those questions with confidence.

Image: studylib.net

The OSHA 30 General Industry test is much more than just a collection of dry facts and figures. It’s about understanding the critical principles of workplace safety and applying them to real-world situations, from preventing falls and managing hazardous chemicals to ensuring safe equipment operation. This article will unravel the key topics covered in the test, giving you insights into what to expect and valuable tips to help you ace those questions.

Unpacking the OSHA 30 General Industry Test: Key Topics

The OSHA 30 General Industry test is designed to assess your understanding of essential safety concepts that apply to a wide range of workplaces. Here’s a breakdown of some key topics you can expect to encounter:

1. OSHA Standards & Regulations

This foundational topic covers the heart of OSHA, delving into its history, purpose, and the comprehensive set of safety standards that govern workplaces across the United States. You’ll gain an understanding of the hierarchy of OSHA standards, from the general duty clause to specific regulations for various industries.

2. Hazard Recognition & Control

Safety starts with identifying potential hazards, and this section focuses on developing your skills in recognizing risks within the workplace. You’ll learn about different types of hazards, including physical, chemical, biological, and ergonomic factors. This section also covers the fundamental principles of hazard control, encompassing strategies like elimination, substitution, engineering controls, and administrative controls.

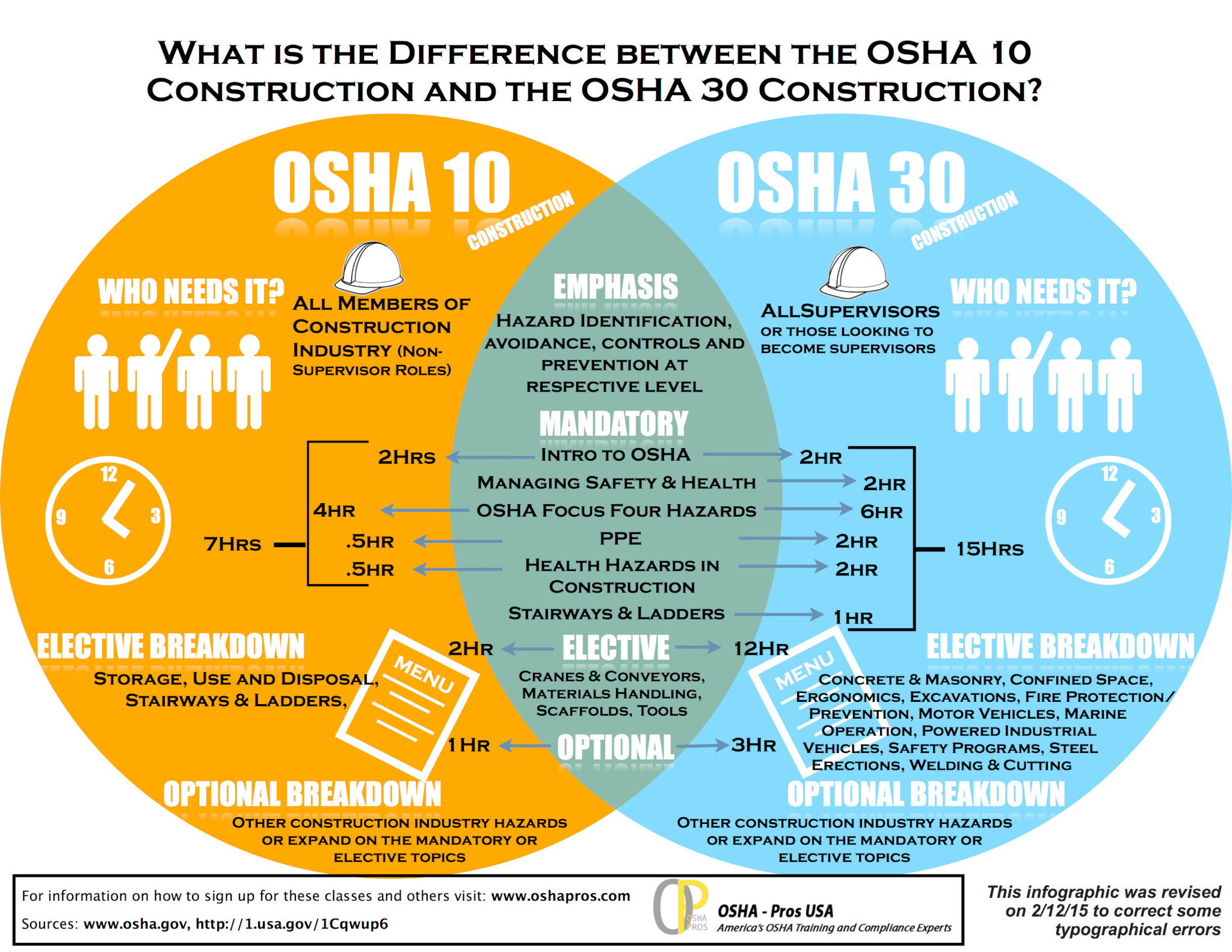

Image: www.mcaa.org

3. Personal Protective Equipment (PPE)

PPE plays a vital role in protecting workers from hazards, and the test will assess your comprehension of its importance. You’ll learn about different types of PPE, including respirators, eye protection, hearing protection, and hand protection, as well as the proper selection and use of PPE for various work activities.

4. Workplace Safety & Health Programs

A robust safety program is essential for maintaining workplace safety and compliance with OSHA regulations. This section will introduce you to the key components of an effective program, including hazard identification and assessment, risk management, training, emergency preparedness, and incident investigation.

5. Fire Safety & Emergency Procedures

Fires pose significant risks to workplaces, making fire safety a crucial aspect of OSHA training. This section covers the dangers of fire, fire prevention measures, proper use of fire extinguishers, fire alarm systems, and evacuation plans. You’ll also explore other emergency procedures such as those for hazardous spills, medical emergencies, and natural disasters.

6. Machine Guarding & Lockout/Tagout

Machines are a cornerstone of many workplaces, but they also present potential dangers. This section delves into the importance of machine guarding, a practice that prevents workers from coming into harm’s way while operating or interacting with machinery. You’ll also explore the lockout/tagout procedures used to isolate machines before performing maintenance or repair tasks, ensuring worker safety during these activities.

7. Working at Heights & Fall Protection

Working at heights is a common practice in various industries, and it comes with an inherent risk of falls. This section highlights the dangers of working at heights, covering OSHA regulations for fall protection equipment such as guardrails, safety nets, and fall arrest systems. You’ll also learn about proper use, inspection, and maintenance of fall protection equipment.

8. Electrical Safety

Electricity is a powerful force, but it can also be hazardous if not handled with proper care. This section focuses on the principles of electrical safety, explaining the risks associated with electrical hazards, such as shocks, burns, and arc flashes. You’ll gain knowledge about safe work practices around electrical circuits, equipment, and installations.

9. Confined Spaces

Confined spaces, such as tanks, pits, and vaults, pose unique safety challenges. This section explores the hazards associated with confined spaces, including oxygen deficiency, toxic atmospheres, and engulfment. You’ll learn about the procedures required for entering confined spaces, including permit systems, atmospheric testing, and rescue plans.

10. Material Handling

Safe material handling is essential for preventing injuries caused by improper lifting, carrying, or movement of objects. This section covers the principles of ergonomic principles and safe lifting techniques to minimize the risk of back injuries, strains, and other musculoskeletal disorders. You’ll also explore the use of material handling equipment and its safe operation.

Test Preparation Strategies and Tips

Now that you have a clear idea of the key topics covered in the OSHA 30 General Industry test, let’s dive into some effective strategies to prepare and ace that exam:

1. Review the Training Materials

The foundation of your preparation lies in thoroughly reviewing the course materials provided during the OSHA 30-Hour training. Pay close attention to the instructor’s lectures, handouts, and any supplementary resources. Make notes, highlight key points, and actively engage with the content.

2. Practice with Sample Questions

Practice makes perfect! Utilize the wide range of sample test questions available online, in your training materials, or in test preparation guides. These questions will help you familiarize yourself with the test format, identify areas where you need further review, and build your confidence.

3. Take a Mock Test

Before the real exam, take a mock test under timed conditions. This will simulate the actual testing environment, allowing you to assess your readiness and familiarize yourself with the test’s pace. Analyze your results, identify areas of weakness, and allocate additional study time to those topics.

4. Seek Clarification When Needed

If you encounter any concepts that remain unclear, don’t hesitate to reach out to your instructor, a fellow student, or an OSHA professional for clarification. Understanding the material thoroughly is crucial for your success in the test.

5. Get Adequate Sleep & Stay Hydrated

On the day of the exam, prioritize a good night’s sleep and make sure to stay well-hydrated. A clear mind and a well-rested body can enhance your performance during the test.

Beyond the Test: Applying OSHA Knowledge

Passing the OSHA 30 General Industry test is not simply about achieving a certificate. It’s about gaining practical knowledge that you can apply to create safer workplaces. By understanding the principles of workplace safety, you become an advocate for your colleagues’ well-being, contributing to a positive and productive work environment.

Osha 30 General Industry Test Answers

Conclusion

The OSHA 30 General Industry test is an important step towards ensuring safer workplaces for everyone. With a thorough understanding of the key topics, diligent test preparation, and a commitment to applying your knowledge, you can ace the test and make a positive impact on workplace safety. Remember, it’s not just about passing the test; it’s about creating a safer and healthier working environment for yourself and those around you.