Have you ever stopped to look up at a towering crane and wondered how those heavy loads are lifted and moved with such precision? Beyond the impressive machinery, lies a world of safety regulations designed to protect workers and prevent accidents. OSHA 10 Module 6: Cranes is a crucial component in understanding these safety protocols, providing essential knowledge for anyone working in or around these powerful machines.

Image: writeness-training.blogspot.com

Whether you are a construction worker, an operator, or simply working near a crane, understanding OSHA 10 Module 6’s crucial safety standards empowers you to work confidently and responsibly around these lifting giants. This comprehensive guide will delve into the intricacies of the module, outlining key topics, explaining essential concepts, and preparing you for the OSHA 10 Module 6: Cranes exam.

Why OSHA 10 Module 6: Cranes Matters

Cranes are powerful tools, able to lift and move heavy loads with relative ease. However, this power comes with inherent risks if proper safety measures are not in place. OSHA 10 Module 6: Cranes is designed to arm you with the knowledge and skills needed to operate and work around cranes safely, minimizing the likelihood of accidents and ensuring the well-being of yourself and others.

Examining the Scope of Module 6: Cranes

OSHA 10 Module 6: Cranes covers a wide range of information, from basic crane types to comprehensive safety protocols. Let’s take a deeper dive into the core topics:

Crane Types: Recognizing the Giants of Construction

Cranes are not all created equal. Understanding the different types of cranes is paramount for safe operation and identification of potential hazards. Module 6 covers the major types, including:

- Tower Cranes: Dominating construction sites with their vertical reach, these cranes are used for lifting heavy loads across vast distances.

- Mobile Cranes: These versatile machines are essential for construction and industrial operations, offering mobility and a wide range of lifting capacities.

- Overhead Cranes: These bridge-like structures traversing industrial environments are ideal for moving heavy items within a designated workspace.

- Crawler Cranes: Equipped with tracks for stability and maneuverability, these cranes excel in challenging terrain.

- Derrick Cranes: Characterized by a fixed base and a rotating boom, these cranes are commonly used in maritime applications.

Image: www.safetymanualosha.com

Crane Components: Understanding the Parts that Make the Whole

Every crane comprises numerous components that work together to perform its intended function. Module 6 dives into the essential elements, highlighting their roles and potential safety hazards:

- Boom: The primary lifting arm extending from the base, responsible for reaching loads and positioning them.

- Hoist: The mechanical system powered by a motor that raises and lowers loads via cables.

- Swivel: The mechanism that enables the boom to rotate, allowing for accurate load positioning.

- Counterweights: Heavy objects strategically placed to counterbalance the weight of the load and the boom, ensuring stability.

- Outriggers: Extensible supports that increase the crane’s stability, particularly when lifting heavy loads.

Setting the Stage for Safety: Inspection and Maintenance

Before every use, cranes require thorough inspections to ensure their mechanical soundness and operating safety. OSHA 10 Module 6 emphasizes the importance of:

- Pre-Shift Inspections: These daily checks involve examining critical components such as brakes, cables, boom, and hydraulic systems.

- Regular Maintenance: Routine inspections and scheduled maintenance are crucial to preventing potential failures and ensuring continued safe operation.

Operations: A Balancing Act of Expertise and Safety

Safe crane operations require a blend of knowledge and expertise. Module 6 details the following key operational guidelines:

- Proper Rigging: Choosing the right lifting equipment, such as slings, chains, or hooks, is vital for load stability and safe handling.

- Load Capacity: Operators must adhere to the crane’s load limits, maintaining safe lifting practices and avoiding overload.

- Communication: Effective communication between the crane operator, spotters, and other personnel can prevent accidents by ensuring everyone is on the same page.

- Weather Conditions: Operating cranes in adverse weather conditions can pose significant risks. Wind gusts, rain, and snow can impact stability and visibility, requiring proper precautions.

Safety Rules: Putting Knowledge into Action

OSHA 10 Module 6: Cranes emphasizes several essential safety rules that must be adhered to at all times during crane operations:

- No Unauthorized Operation: Only trained and certified personnel should operate cranes.

- Clearance: Maintaining adequate clearance between the crane and surrounding structures, power lines, and personnel is critical for a safe working environment.

- Personal Protective Equipment (PPE): Crane operators and personnel should wear appropriate PPE, including hard hats, safety shoes, and high-visibility vests.

- Emergency Procedures: Being familiar with emergency procedures, including the use of emergency stops and communication channels, can greatly minimize the severity of accidents.

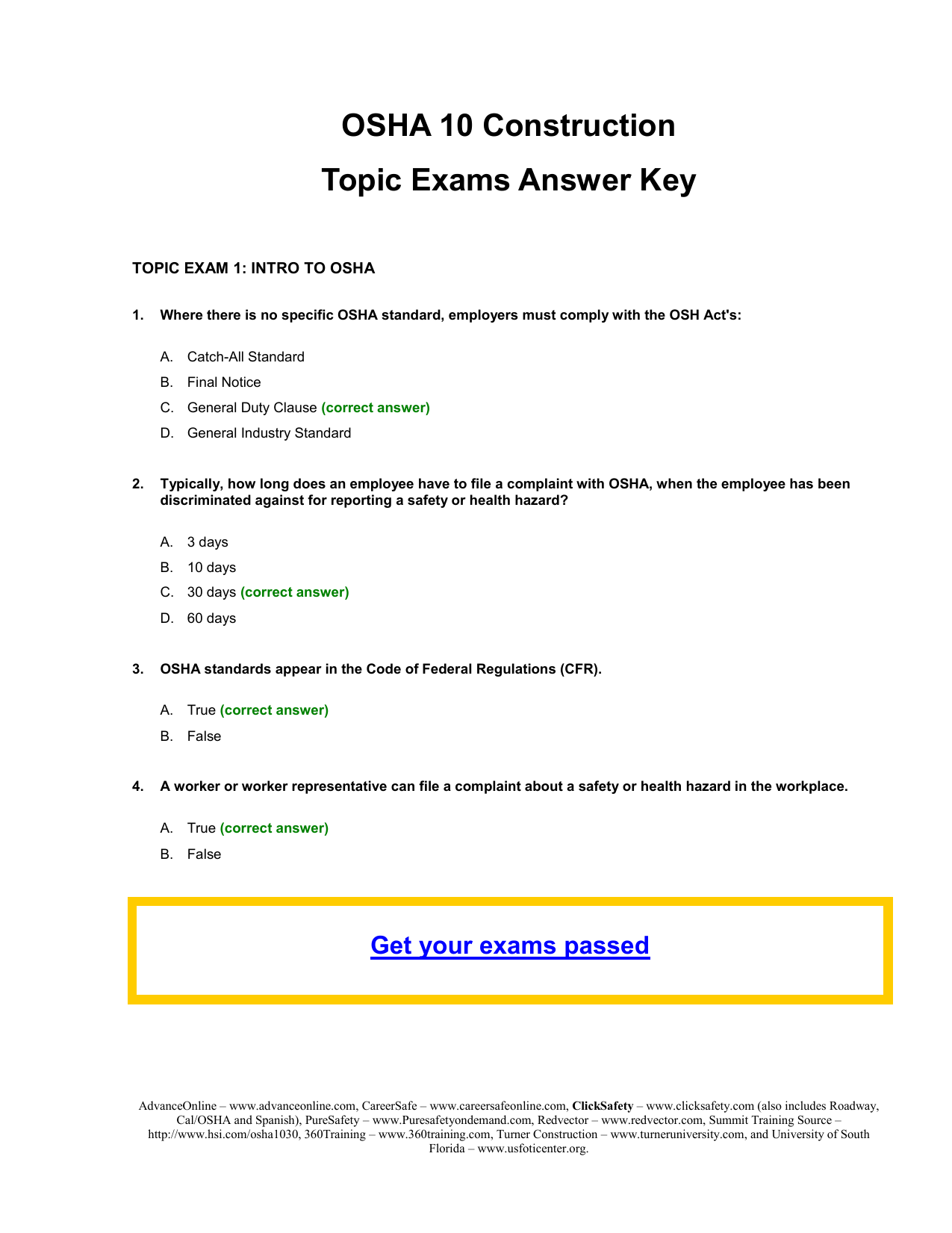

Ready for the OSHA 10 Module 6: Cranes Exam

Having a strong foundation in the material covered in OSHA 10 Module 6 is essential for passing the exam. A thorough understanding of crane types, components, inspection protocols, and safe operating procedures will provide you with the confidence to succeed.

Here are some tips for preparing for the exam:

- Review the Module Material: Carefully read through the module’s content, focusing on key concepts, terminology, and safety guidelines.

- Practice Questions: Use practice exams to test your knowledge and identify areas that require further study.

- Familiarize Yourself with Exam Format: Understand the exam structure, including the number of questions, the types of questions (multiple choice, true/false), and the time limit.

- Get a Good Night’s Sleep: Ensure you’re well-rested before the exam to improve your concentration and memory recall.

Osha 10 Module 6 Cranes Exam

Conclusion: Building a Foundation for Crane Safety

OSHA 10 Module 6: Cranes plays a vital role in ensuring safe operations around these powerful lifting machines. Understanding crane types, components, inspection procedures, and safe operational practices is essential for reducing risks and protecting workers. Take the time to thoroughly study the module material and prepare for the exam to gain the skills and knowledge needed for a safe and successful career in the industry.

Have you taken the OSHA 10 Module 6: Cranes exam? Share your experiences and insights in the comments below. Let’s prioritize safety and work together to create a safer environment for everyone around cranes.