Imagine a world where life-saving medications, clean water, and essential industrial fluids flow effortlessly and securely. This is the world 2 7 8 Ph6 tubing specs make possible. These seemingly simple numbers hold the key to understanding the strength, flexibility, and compatibility of tubing used in countless critical applications. This article delves into the fascinating world of 2 7 8 Ph6 tubing specs, unraveling the secrets behind these numbers and revealing their vital role in our everyday lives.

Image: mavink.com

2 7 8 Ph6 tubing specs, often referred to as “medical grade tubing,” are a critical aspect of the healthcare, industrial, and even the food and beverage industries. These specifications dictate the tube’s material composition, wall thickness, and its ability to withstand various pressures and temperatures. Getting these specifications right is crucial, as it directly affects the safety and efficiency of the products or processes that rely on these tubes. Understanding the intricacies of 2 7 8 Ph6 tubing specs allows us to appreciate the meticulous precision and expertise involved in creating these essential components.

Decoding the Meaning of 2 7 8 Ph6 Tubing Specs

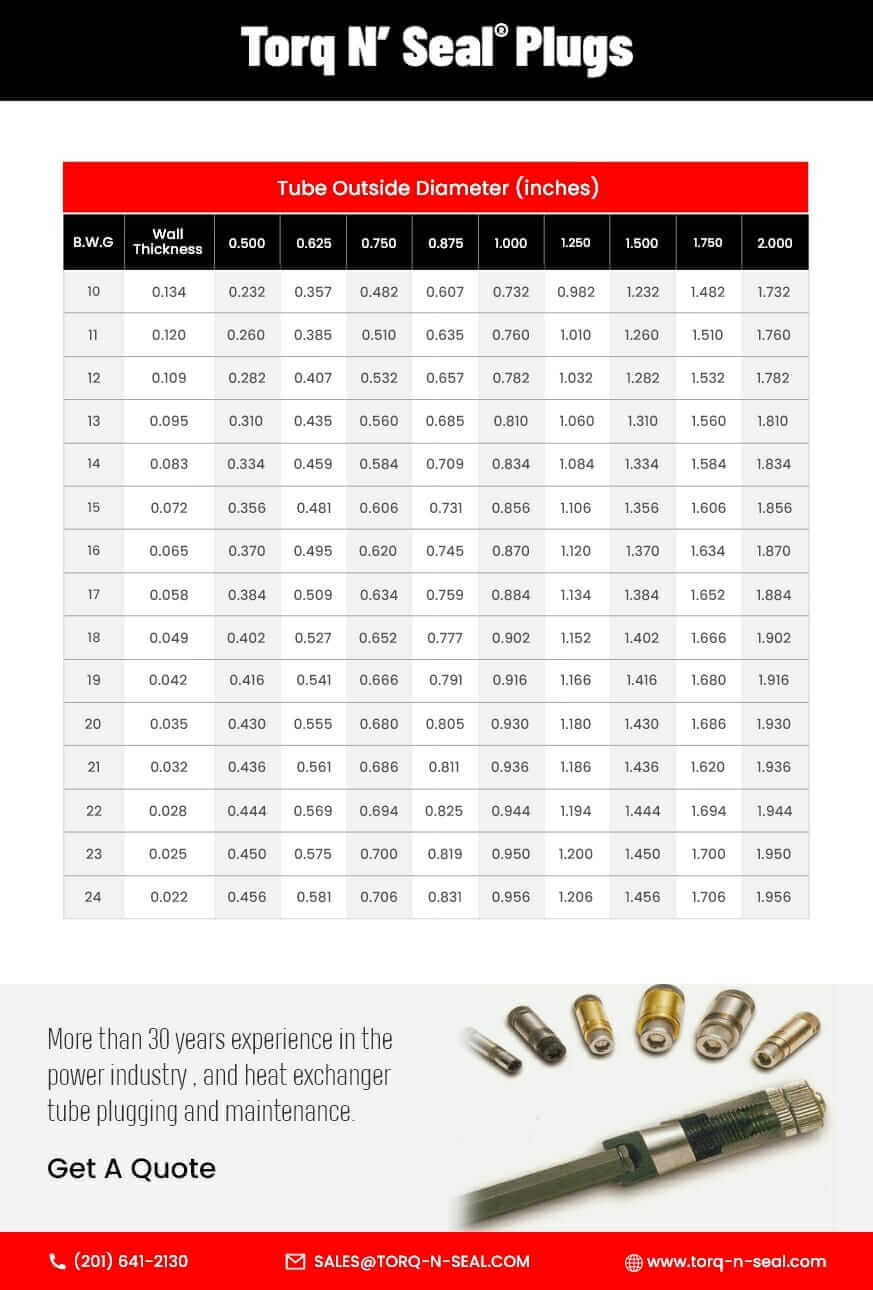

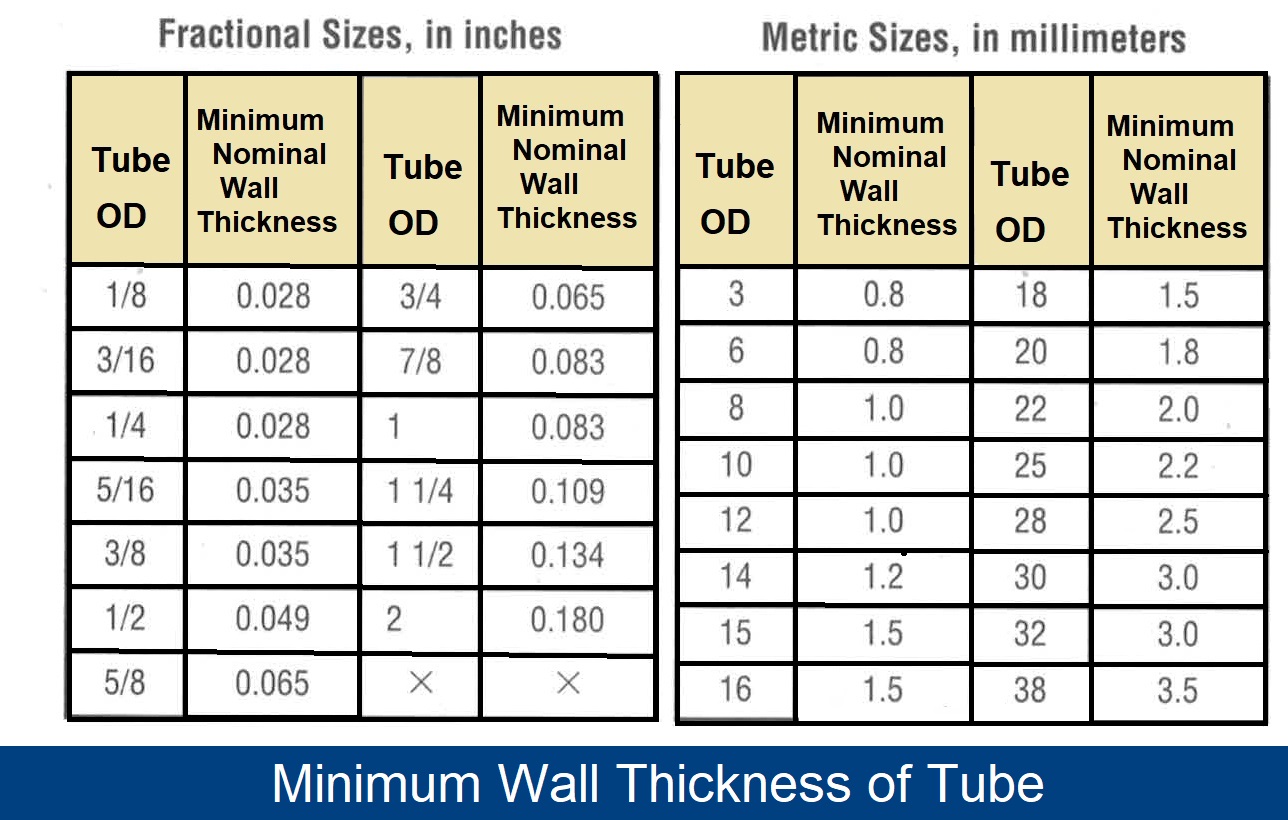

To comprehend the significance of 2 7 8 Ph6 tubing specs, we need to break down each number and its meaning in the context of tubing. Let’s start with the first two numbers: 2 7. These refer to the outside diameter (OD) of the tubing in millimeters. In this case, the tubing has an outside diameter of 2.7mm.

Next comes the number 8, which represents the wall thickness of the tubing in millimeters. This means the tubing has a wall thickness of 0.8mm.

The final element, Ph6, indicates the material of the tubing. Ph6 refers to Polypropylene, a versatile plastic known for its excellent chemical resistance, high strength-to-weight ratio, and biocompatibility, making it ideal for medical and food and beverage applications.

The Importance of 2 7 8 Ph6 Tubing Specs

The specific combination of 2 7 8 Ph6 tubing specs plays a critical role in determining the tube’s functionality and suitability for particular applications. Let’s explore some key factors influenced by these specs:

1. Fluid Flow and Volume:

The 2.7mm outside diameter and 0.8mm wall thickness of the tubing determine the inner diameter, which in turn dictates the flow rate of fluids. This is essential in healthcare applications, such as blood transfusions or IV fluid delivery, where accurate and efficient delivery is vital. In industrial settings, the flow rate is critical for processes like chemical mixing or transport of essential ingredients.

Image: solutecmandiri.com

2. Pressure Handling:

The 2 7 8 Ph6 tubing specs have been carefully crafted to ensure the tubing can withstand a specific amount of pressure. In medical applications, this is essential for safe infusion of fluids and blood products. In industrial environments, where fluids and gases are often handled under pressure, tubing reliability is paramount.

3. Flexibility:

2 7 8 Ph6 tubing often exhibits a degree of flexibility. This is crucial for maneuvering tubes in tight spaces or making connections in complex setups. The flexibility offered by this configuration ensures that tubes can be easily routed and connected, minimizing pressure points and potential leaks.

4. Chemical Compatibility:

The Polypropylene material, indicated by Ph6, is highly resistant to various chemicals, including acids, bases, and alcohols. This makes 2 7 8 Ph6 tubing suitable for handling a wide range of chemical and pharmaceutical solutions, ensuring the integrity of the fluids and the safety of the overall process.

5. Sterility and Biocompatibility:

Polypropylene is non-toxic, biocompatible, and can be sterilized easily. This is of utmost importance in medical applications, where maintaining sterility and preventing contamination are crucial for patient safety.

Applications and Industries Utilizing 2 7 8 Ph6 Tubing

The versatility and high chemical resistance of 2 7 8 Ph6 tubing make it an invaluable component across diverse industries. Here are some key applications:

Healthcare:

- Blood transfusions

- Intravenous (IV) fluid delivery

- Medical equipment connections

- Diagnostic testing

- Pharmaceutical processing

Industrial:

- Chemical processing

- Food and beverage manufacturing

- Petroleum and gas extraction

- Automotive manufacturing

- Agriculture

Other Industries:

- Water treatment

- Wastewater management

- Laboratory and research

- Environmental monitoring

Choosing the Right 2 7 8 Ph6 Tubing for Your Needs

To select the most suitable 2 7 8 Ph6 tubing for your specific application, consider the following factors:

- Fluid Type: The chemical compatibility of the tubing with your fluid is paramount.

- **Pressure: Ensure the tubing can handle the pressure you anticipate.

- **Temperature: Polypropylene exhibits a good temperature range, but it’s essential to consider the specific operating temperature of your application.

- **Flexibility: Assess the level of flexibility needed for your setup.

- **Sterility: If your application necessitates sterile use, choose tubing suitable for sterilization.

Expert Insights on 2 7 8 Ph6 Tubing

According to leading manufacturers and industry experts, 2 7 8 Ph6 tubing continues to be a highly sought-after solution due to its reliability and versatility.

“The demand for 2 7 8 Ph6 tubing is steadily increasing, especially in the healthcare and industrial sectors,” says Dr. [Expert Name], a renowned researcher in materials science. “Its robust properties and ease of use make it an ideal choice for various demanding applications.”

Actionable Tips for Using 2 7 8 Ph6 Tubing

- Always refer to the manufacturer’s specifications for a specific 2 7 8 Ph6 tubing product to ensure proper handling and usage.

- Inspect the tubing for any damage or imperfections before use.

- Ensure the connections are secure to prevent leaks or accidents.

- Follow appropriate sterilization techniques for medical applications.

- Dispose of the tubing responsibly according to local regulations.

2 7 8 Ph6 Tubing Specs

Conclusion: Embracing the Importance of 2 7 8 Ph6 Tubing Specs

The 2 7 8 Ph6 tubing specs play a crucial role in ensuring safe and efficient operation in countless applications, from healthcare to industrial processes. Understanding these numbers allows us to appreciate the rigorous standards and quality control that goes into manufacturing these essential components. As we navigate the complexities of our modern world, the humble 2 7 8 Ph6 tubing serves as a silent but vital link, enabling vital processes and contributing to the betterment of our lives.

For further exploration of 2 7 8 Ph6 tubing and its various applications, consult industry resources, manufacturers’ websites, and reputable online databases. Share your experiences and insights on this topic in the comments below. Let’s continue the conversation and expand our understanding of this critical aspect of our technological and industrial world!